Understanding the workings of a 3 wire speed sensor is crucial for vehicle and machinery maintenance. These sensors play a key role in system performance.

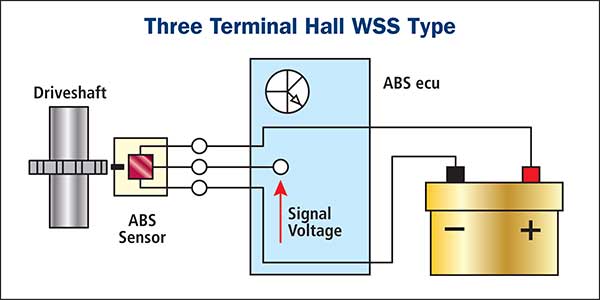

A 3 wire speed sensor operates by measuring the rate at which a component rotates, translating this mechanical motion into an electrical signal that is interpretable by a vehicle's computer. Within the realm of automotive and industrial machinery, the 3 wire speed sensor emerges as an unsung hero. This device may seem small, but its job is vital for the accurate monitoring of speed, which in turn ensures the smooth operation of various systems. The sensor uses a clever combination of electrical components to relay information about rotational speed. This data is critical for functions such as anti-lock braking systems and engine management. With a straightforward design, the sensor comprises three essential wires – each serving a distinct purpose to ensure that performance is both precise and reliable. This introductory guide will shed light on how these sensors work, why they are important, and the basic principles behind their operation. Understanding these sensors can help anyone grasp the complex ballet of machinery and electronics that keep vehicles and equipment running safely and efficiently. Credit: premierautotrade.com.au

Credit: premierautotrade.com.au

Introduction To 3 Wire Speed Sensors

Imagine a car that knows its speed without looking at the road. It sounds like magic, right? Well, that's what a 3 wire speed sensor does. It tells us how fast something turns or moves. This tiny device is a big deal in many machines. Let's learn how it works and where we find it.Core Functions

At its heart, a 3 wire speed sensor has one job. It checks how fast parts move. It does this by creating electrical signals. These signals change with the speed of the moving part. A computer then reads these signals. It uses them to control or monitor the speed. Simple, yet so important.Common Applications

You'll find these sensors in many places. Cars use them to measure wheel speed. Factories have them in machines to track production. Even your smartphone might use one to count your steps. They are everywhere, keeping things running smooth and smart.Fundamentals Of Speed Sensing

Understanding how things move is key. Speed sensing plays a big part in this. Let's dive into the fundamentals of speed sensing.Speed Sensing Principles

At its core, speed sensing measures how fast something moves. Simple, right? It's all about tracking movement over time. This info helps in many areas. Like car speedometers or controlling machines.- Direct measurement - Counts how far in a set time.

- Indirect measurement - Uses other data to calculate speed.

Magnetic Sensors Explained

Magnetic sensors stand out in speed sensing. They use magnets and electricity. Here’s how:- A magnet moves near a sensor.

- It creates an electrical signal.

- The sensor sends this signal to a device.

- The device calculates speed from this signal.

Anatomy Of A 3 Wire Speed Sensor

Understanding the 'Anatomy of a 3 Wire Speed Sensor' is crucial for anyone dealing with vehicle electronics. These sensors play a vital role in monitoring the speed of various components. Let's dive into what makes up these innovative devices.Key Components

A 3 wire speed sensor consists of several key parts:- Magnet – Creates a magnetic field

- Coil – Detects changes in the magnetic field

- Output Signal Wire – Carries the signal

- Power Supply Wire – Provides voltage

- Ground Wire – Completes the circuit

Sensor Circuitry

The circuitry within a 3 wire speed sensor is simple yet effective:- Voltage is supplied to the sensor.

- The magnetic field reacts to metal teeth passing by the sensor.

- As teeth pass, the magnetic field fluctuates.

- The coil converts these fluctuations into an electrical signal.

- This signal is then sent through the output wire.

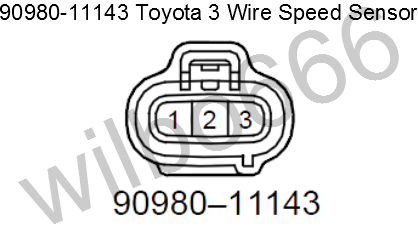

Credit: wilbo666.pbworks.com

Credit: wilbo666.pbworks.com

Electrical Operation And Signal Output

Electrical Operation and Signal Output are key in 3 wire speed sensors. These sensors play a vital role in modern vehicles. They measure the speed of a car's wheel or shaft. Let's dive into the power supply and how they create signals.Power Supply Connection

A 3 wire speed sensor connects to a power source. This source feeds it electricity. The sensor has three wires:- Power: Usually red, supplies voltage.

- Ground: Often black, completes the circuit.

- Signal: Typically yellow, sends data.

Signal Generation Process

The signal generation in a 3 wire speed sensor is a precise process. It works like this:- A part called a reluctor passes by the sensor.

- It changes the magnetic field around the sensor.

- This change creates a voltage in the sensor's coil.

- The voltage makes a wave-like signal.

- The signal's frequency shows speed changes.

Installation Considerations For Optimal Performance

For those installing a 3-wire speed sensor, performance matters. Proper installation ensures accurate data. Let's dive into how to optimize installation.Mounting Guidelines

Location is key. Choose a spot free from high vibration. Sensors need stability to work well.- Keep away from heat sources. Heat can damage sensors.

- Ensure the sensor faces the target. It needs a clear path.

- Use the right mount. A firm hold prevents movement.

Wiring Best Practices

Correct wiring is crucial for sensor accuracy. Follow these steps for best results.- Check the manual. It has wiring diagrams.

- Use quality wires. They reduce signal noise.

- Keep wires short. Long wires can lose signal.

- Secure connections tightly. Loose wires cause errors.

Troubleshooting Common Issues

When a 3-wire speed sensor fails, vehicles may experience problems. The sensor's role is vital. It measures wheel speed and sends data to the car's computer. This data affects anti-lock braking and traction control. Let's explore how to solve common issues with these sensors.Diagnosing Signal Problems

Signal issues can cause erratic readings. A multimeter checks the sensor's output. Connect the multimeter to the sensor's signal and ground wires. Spin the wheel by hand. A changing voltage indicates a working sensor. No change suggests a problem. Check the sensor ring too. It must be clean and undamaged.Addressing Electrical Faults

Electrical faults disrupt sensor function. Start by inspecting the wires. Look for breaks, corrosion, and loose connections. Repair or replace damaged wires. Connections must be secure. Next, check the voltage supply. The sensor needs the right voltage to work. Use the vehicle's manual for the correct voltage. Fixing these issues can restore sensor performance.Advancements In Speed Sensor Technology

Exploring the latest in speed sensor tech, a 3-wire sensor stands out for its simplicity and efficiency. It sends signals to measure vehicle speed, using power, ground, and output connections to relay information accurately. Advancements in speed sensor technology have marked a significant leap forward. These devices play a critical role in various applications. From vehicles to industrial machinery, they ensure efficiency and safety. The evolution in this field focuses on accuracy and reliability. Let's delve into the latest developments.Innovations In Sensor Design

New designs in speed sensors bring improvements. They are now smaller, yet more powerful. This change allows easy integration into different systems. Durability has also increased. Sensors now withstand harsh conditions better. This means they last longer and perform reliably. Smart technology integration is another key feature. Sensors can now communicate data directly to systems. This allows for real-time monitoring and adjustments. Such advancements make operations smoother and safer.Future Trends

Looking ahead, the trend is clear. Sensors will get even smarter and more efficient. Wireless technology will play a big role. This will make installation and maintenance easier. Energy efficiency is another focus area. Future sensors will use less power. This is crucial for battery-operated devices. Lastly, the use of AI and machine learning is on the rise. These technologies will enable sensors to predict failures. This predictive ability will save time and money. It will also enhance safety across many applications. The journey of speed sensor technology is exciting. It moves towards more innovative, efficient, and intelligent solutions. These advancements promise to make our systems and devices safer and more reliable.Real-world Case Studies

Exploring how 3 wire speed sensors impact various industries offers valuable insights. Real-world case studies reveal the practical applications and benefits of these devices. Let's delve into specific examples from the automotive and industrial sectors to understand their significance.Automotive Industry Insights

3 wire speed sensors play a crucial role in vehicle performance and safety. Modern cars use these sensors to monitor wheel speed. This data helps with ABS and traction control. Manufacturers test sensors under extreme conditions to ensure reliability.- Enhanced brake systems: Sensors provide real-time wheel speed data, improving brake response.

- Fuel efficiency: Accurate speed readings help optimize engine performance, saving fuel.

- Diagnostic systems: Sensors alert when there's a malfunction, aiding prompt maintenance.

Industrial Machinery Applications

In factories, 3 wire speed sensors help maintain machinery efficiency. They monitor conveyor belts, ensuring products move at the correct speed. This precision prevents jams and reduces downtime. Sensors also contribute to worker safety by detecting anomalies in machine operation.| Application | Benefit |

|---|---|

| Conveyor belt speed monitoring | Prevents product damage and jams |

| Machine tool speed control | Enhances tool life and precision |

| Rotational machinery | Ensures safe and stable operation |

Faqs On 3 Wire Speed Sensors

Understanding the workings of a 3 wire speed sensor can seem complex. This section aims to demystify the topic. It answers common questions and provides practical advice.Choosing The Right Sensor

Selecting a suitable 3 wire speed sensor is crucial. Consider application needs and sensor specifications. Match sensor range with your system's requirements. Ensure compatibility with existing equipment.Maintenance And Longevity Tips

To extend sensor life, perform regular checks. Clean the sensor surface gently. Avoid harsh chemicals. Follow the manufacturer's guidelines. Use diagnostic tools to detect early signs of wear.- Check connections for corrosion.

- Replace damaged wiring promptly.

- Keep sensor firmware updated.

- Conduct calibration at recommended intervals.

Credit: www.techshopmag.com

Credit: www.techshopmag.com

Frequently Asked Questions

What Is A 3 Wire Speed Sensor?

A 3 wire speed sensor is a device used to measure the speed of a moving object. It has three connections: power, ground, and signal. The sensor generates a signal proportional to the speed, which is then interpreted by a control system.How Does A 3 Wire Speed Sensor Operate?

The sensor operates by detecting changes in a magnetic field as an object moves. It sends a voltage or frequency signal that varies with speed to the control system. This allows for accurate speed measurement.Benefits Of Using A 3 Wire Speed Sensor?

3 wire speed sensors offer accurate, reliable speed measurements. They are durable, resistant to interference, and can be used in a wide range of applications. This makes them valuable in automotive, industrial, and aerospace sectors.Installation Tips For 3 Wire Speed Sensors?

For optimal performance, mount the sensor securely near the moving part. Ensure the wiring is correct: power to the power wire, ground to the ground wire, and the signal wire to the control system. Avoid electrical noise for accurate readings.Conclusion

Understanding a 3 wire speed sensor is straightforward. It uses electricity to monitor speed. The sensor's three wires have specific roles. One provides power, another grounds the circuit, and the third sends signals. These signals tell how fast an object moves. Mechanics and hobbyists alike find this tool essential. Remember, proper installation and maintenance ensure accurate readings. Embrace the simplicity of this device for your speed measurement needs. Keep learning, keep experimenting. Stay curious about how things work. Your projects will thank you for it.Disclosure

Some links may be affiliate links. That means we may earn a small commission at no extra cost to you.