5 Common Mistakes When Replacing a Distributor Cap That Could Stop Your Car Incorrect installation and failing to check connections can prevent your car from starting. Misaligned parts and ignoring the firing order can also cause issues.

Replacing a distributor cap might seem simple, but several common mistakes can derail your efforts. Incorrect installation and failure to check connections can lead to significant problems, including the car not starting.

Many people overlook the importance of aligning parts properly and adhering to the correct firing order. Dirt and debris can also compromise the installation, causing performance issues.

Taking the time to understand these common pitfalls can save you from unnecessary headaches and ensure your car runs smoothly. Proper attention to detail during the replacement process will help maintain your vehicle's reliability.

Choosing The Wrong Cap

Choosing the wrong distributor cap can cause serious car problems. It's one of the most common mistakes people make. Let's explore the key areas to focus on.

Material Matters

The material of the distributor cap is crucial. Always pick a cap made of high-quality plastic or composite materials. These materials can withstand high temperatures and resist corrosion. Poor-quality materials can crack or warp. This can cause misfires and other engine problems. Always check the material before buying.

Compatibility Issues

Compatibility is another important factor. The distributor cap must match your car's make and model. Using the wrong cap can lead to poor engine performance. Always consult your car’s manual. Make sure the cap fits perfectly. A mismatched cap can cause the engine to fail.

Key Points:

- Material Matters: Choose high-quality materials like plastic or composite.

- Compatibility Issues: Ensure the cap matches your car’s make and model.

Ignoring The Rotor

Ignoring The Rotor

Ignoring The Rotor

Many car owners focus solely on the distributor cap. They forget the rotor. The rotor is crucial. It distributes the electrical current to spark plugs. Ignoring the rotor can cause serious problems.

Related Post

5 Reasons Spark Plug Wires May Not Be Compatible With Your Vehicle

The Importance of a Distributor in Your Car: More Than Just Spark

10 Warning Signs Your Car’S Spark Plugs Need Replacing

Expert Tips: Testing Club Car Ignition Coil Parts Like a Pro

Mastering Car Ignition Coils: A Step-By-Step Testing Guide

Rotor Wear

Over time, the rotor wears out. This wear affects its performance. A worn rotor can't deliver current effectively. Check the rotor for signs of wear. Look for cracks, burns, or erosion. Replace the rotor if you see any damage.

Matching The Cap

The rotor and cap must match. They work together to distribute current. Using the wrong rotor can cause misfires. Always ensure the rotor fits the cap properly. Consult your car's manual for the right specifications.

| Common Signs of Rotor Wear | Effects |

|---|---|

| Cracks | Electrical leakage |

| Burns | Reduced current flow |

| Erosion | Poor performance |

Pro Tip: Always inspect the rotor when replacing the distributor cap. Ensure it's in good condition. This prevents future problems and keeps your car running smoothly.

Improper Installation

Replacing a distributor cap might seem easy, but errors can cause problems. One common mistake is improper installation. This can prevent your car from starting or running smoothly. Let's break down two critical aspects: incorrect alignment and securing the cap.

Incorrect Alignment

Incorrect alignment of the distributor cap is a frequent issue. Each distributor cap has specific notches and grooves. These must align perfectly with the distributor body. Misalignment can cause poor contact between the rotor and cap terminals.

This can lead to misfires and engine performance issues.

- Ensure the cap's notches match the distributor body.

- Double-check the position before securing the cap.

Securing The Cap

Another mistake is not securing the cap properly. A loose cap can cause vibrations. This affects the rotor's connection with the cap terminals. Tighten the cap evenly and firmly. Use the correct screws or clips provided.

- Place the cap correctly on the distributor.

- Use the correct tools to secure it.

- Ensure even tightness on all sides.

Following these steps ensures a proper fit. This helps maintain engine performance and reliability.

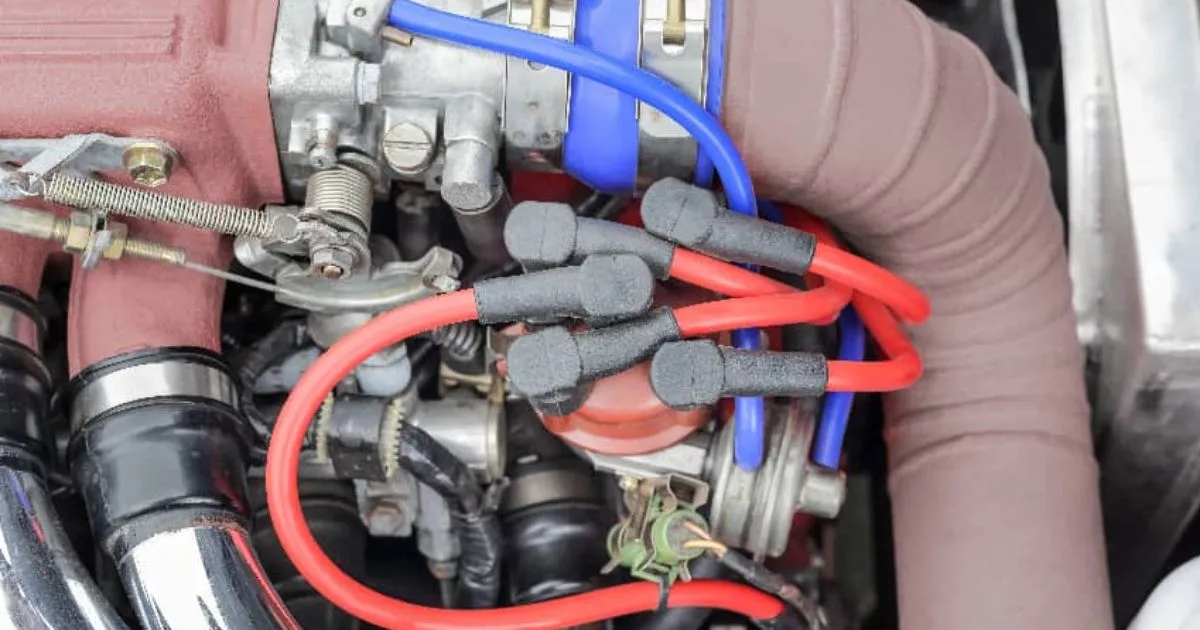

Neglecting The Wires

When replacing a distributor cap, neglecting the wires can lead to serious problems. Ignoring these crucial components can cause your car to stop running. Let's explore some common mistakes related to wires.

Wire Condition

Inspect the wires for wear and tear. Old wires can be brittle and break easily. Always check for cracks or cuts in the insulation. Damaged wires can cause misfires or complete engine failure.

| Condition | Impact |

|---|---|

| Cracked Insulation | May cause short circuits |

| Frayed Ends | Leads to poor connection |

| Brittle Wires | Prone to breaking |

Proper Connection

Ensure all wires are properly connected. Incorrect connections can prevent your car from starting. Each wire must connect to the correct terminal.

A loose wire can cause intermittent issues.

- Double-check all connections.

- Ensure wires snap into place securely.

- Match each wire to the correct cylinder.

Remember, wires play a vital role in the ignition system. Neglecting them can lead to bigger problems.

Overlooking Maintenance

Overlooking Maintenance

Overlooking Maintenance

One of the most common mistakes when replacing a distributor cap is overlooking maintenance. Regular maintenance ensures your car runs smoothly and avoids costly repairs. Neglecting these steps can lead to significant issues with your vehicle.

Regular Inspection

Regular inspection of your distributor cap is crucial. Check for cracks or signs of wear. A damaged distributor cap can cause your car to misfire or not start at all. Use a flashlight to see better and ensure nothing is broken.

Creating a maintenance schedule helps keep your car in top shape. Inspect the distributor cap every 6,000 miles or six months. This simple step can save time and money.

Cleaning Contacts

Cleaning the contacts inside the distributor cap is important. Dirty contacts can lead to poor engine performance. Use a clean cloth or a small brush for this task.

Ensure all debris is removed for a better connection. A clean distributor cap ensures a proper electrical connection. This step prevents misfires and improves engine efficiency. Make sure to clean contacts during each inspection.

Skipping The Gasket

Replacing a distributor cap involves precision. One common mistake is skipping the gasket. This small component is often overlooked, yet it's critical for your car's performance. Let's explore why skipping the gasket can cause issues.

Importance Of Seals

The gasket acts as a seal. It prevents dirt and moisture from entering the distributor. Without the gasket, contaminants can cause major problems. A secure seal ensures the distributor cap fits snugly. This fit is crucial for maintaining optimal performance. A loose fit can lead to electrical issues and misfires.

Preventing Leaks

Gaskets also prevent leaks. Oil and other fluids can seep into the distributor without a gasket. This can lead to corrosion and electrical failures. Leak prevention is vital for the longevity of your distributor. A simple gasket can save you from costly repairs down the line.

Here are some key points to remember:

- Always replace the gasket when changing the distributor cap.

- Ensure a tight fit to prevent dirt and moisture entry.

- Check for leaks regularly to maintain distributor health.

| Issue | Consequence |

|---|---|

| Skipping the Gasket | Dirt and moisture enter the distributor |

| Loose Fit | Electrical issues and misfires |

| Leaks | Corrosion and electrical failures |

Not Checking Timing

Not Checking Timing

Not Checking Timing

Replacing a distributor cap is crucial for your car’s ignition system. One common mistake is not checking the timing. Incorrect timing can lead to engine problems. This section will cover the importance of timing adjustments and how it affects engine performance.

Timing Adjustments

Timing adjustments ensure that the spark plug fires at the right moment. This is essential for the combustion process. Without proper timing, the engine can misfire or fail to start.

- Use a timing light to check the timing.

- Adjust the distributor cap if the timing is off.

- Refer to your car’s manual for specific timing settings.

Incorrect timing can also cause excessive wear on engine parts. This can lead to costly repairs down the line.

Engine Performance

Correct timing directly impacts engine performance. When the timing is correct, the engine runs smoothly. It also improves fuel efficiency.

| Correct Timing | Incorrect Timing |

|---|---|

| Smooth engine operation | Engine misfires |

| Better fuel efficiency | Poor fuel efficiency |

| Longer engine life | Excessive wear and tear |

Incorrect timing can also affect your car’s emissions. This can lead to failing emission tests. Make sure to double-check the timing after replacing the distributor cap.

Ignoring Symptoms

One of the most common mistakes when replacing a distributor cap is ignoring symptoms of a failing component. Recognizing these symptoms early can save you time and money. Ignoring them may lead to bigger problems.

Engine Misfires

A misfiring engine is a clear sign of a faulty distributor cap. The engine may run rough or stall unexpectedly. This happens because the spark plugs aren't getting the right signals. Ignoring this symptom can result in severe engine damage. Always check the distributor cap if you notice misfires.

Starting Issues

If your car struggles to start, the distributor cap could be the culprit. A worn or damaged cap can't deliver the necessary spark. This makes the engine fail to ignite properly. Replacing the distributor cap promptly can solve this issue. Ignoring it will leave you stranded.

Frequently Asked Questions

What Are Common Distributor Cap Replacement Mistakes?

Not securing the cap properly, using incorrect parts, neglecting to clean the area, and incorrect wire placement are common mistakes.

Can A Loose Distributor Cap Stop A Car?

Yes, a loose distributor cap can disrupt the ignition process, preventing the car from starting or running smoothly.

How Important Is Cleaning The Distributor Area?

Cleaning the area is crucial to prevent dirt and debris from interfering with the new distributor cap's function.

What Happens If Wires Are Incorrectly Placed?

Incorrect wire placement can lead to engine misfires, poor performance, or the car not starting at all.

Related Post

The True Cost of Fixing Your Car’S Glow Plugs

The Ultimate Guide to Spark Plug Cable Compatibility for Your Vehicle

How to Budget for Ignition Coil Replacement: Tips And Tricks

How to Effectively Test Your Magneto Ignition Coil: Tips And Tricks

How an Car Ignition Box Works: From Key Turn to Engine Roar

Conclusion

Avoiding these common mistakes can ensure a smooth distributor cap replacement. Proper installation keeps your car running efficiently. Always double-check your work to prevent issues. Follow these tips to keep your vehicle in top shape. Your engine will thank you for the extra attention. Happy driving!

Disclosure

Some links may be affiliate links. That means we may earn a small commission at no extra cost to you.